- 6522 views

Explosive atmospheres can be caused by flammable gases, mists or vapours or combustible dusts. If there is enough of the substance, mixed with air, then all it needs is a source of ignition to cause an explosion.

Explosions can cause loss of life and serious injuries as well as significant damage. Preventing release of dangerous substances which can create explosive atmospheres, and preventing sources of ignition are two widely used ways of reducing the risk. Let’s see how ATEX certification helps in this.

What is ATEX Certification?

ATEX Directive 2014/34/EU is an important European directive that lays down Essential Health and Safety Requirements (EHSRs) relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres.

Directive 2014/34/EU provides requirements for electrical and non-electrical equipment, intended for use in potentially explosive dust or gaseous atmosphere.

Why ATEX Certification?

Any equipment or protective equipment which could become a source of ignition in a potentially explosive environment requires ATEX certification. This is to ensure that the equipment will work safely in explosive environment without causing any accident if used as per the manufacturer’s recommendations. Equipment used in explosive atmosphere within the European Union (EU) and the European Economic Area (EEA) must be ATEX certified.

Any equipment or protective equipment which could become a source of ignition in a potentially explosive environment requires ATEX certification. This is to ensure that the equipment will work safely in explosive environment without causing any accident if used as per the manufacturer’s recommendations. Equipment used in explosive atmosphere within the European Union (EU) and the European Economic Area (EEA) must be ATEX certified.

How is a spark created?

Result of Impact

A spark is created by an impact between a hard metal and a soft metal. The impact produces high amount of heat due to friction. The spark we see are the chipped off tiny particles from the soft metal which are red hot due to heat generated from friction. Thus, for a spark to happen -

- The impact energy should be high

- The impact should be between a soft and a hard metal

Antistatic Discharge

When two non-conductors rub against each other a charge is developed. Due to prolonged rubbing the charge accumulated becomes so high that it is discharged to the earth which is at zero potential (Charge flows from higher potential to lower potential). The clouds are a great example. When two clouds rub against each other a huge amount of static charge is produced. When the clouds are no longer able to hold the charge, it is dissipated to the earth and we see a lightening.

The same phenomenon occurs on a minute scale when charge accumulated by the rubbing of the harness webbing grows so large that the webbing can no longer hold it. It is dissipated to the ground which is visible to us as a spark (miniature lightening). However, this spark is sufficient to ignite a gaseous mixture and create an explosion.

KARAM offers its No SPARK range of Harnesses and Lanyards which are antistatic in nature hence do not create any sparking. This range offers the perfect solution for safe working at height in explosive atmospheres. All metal components on the ‘NO SPARK’ range of Harnesses are made up of Stainless Steel which is an excellent conductor of electricity, hence prevents any build-up of charge.

Certification:

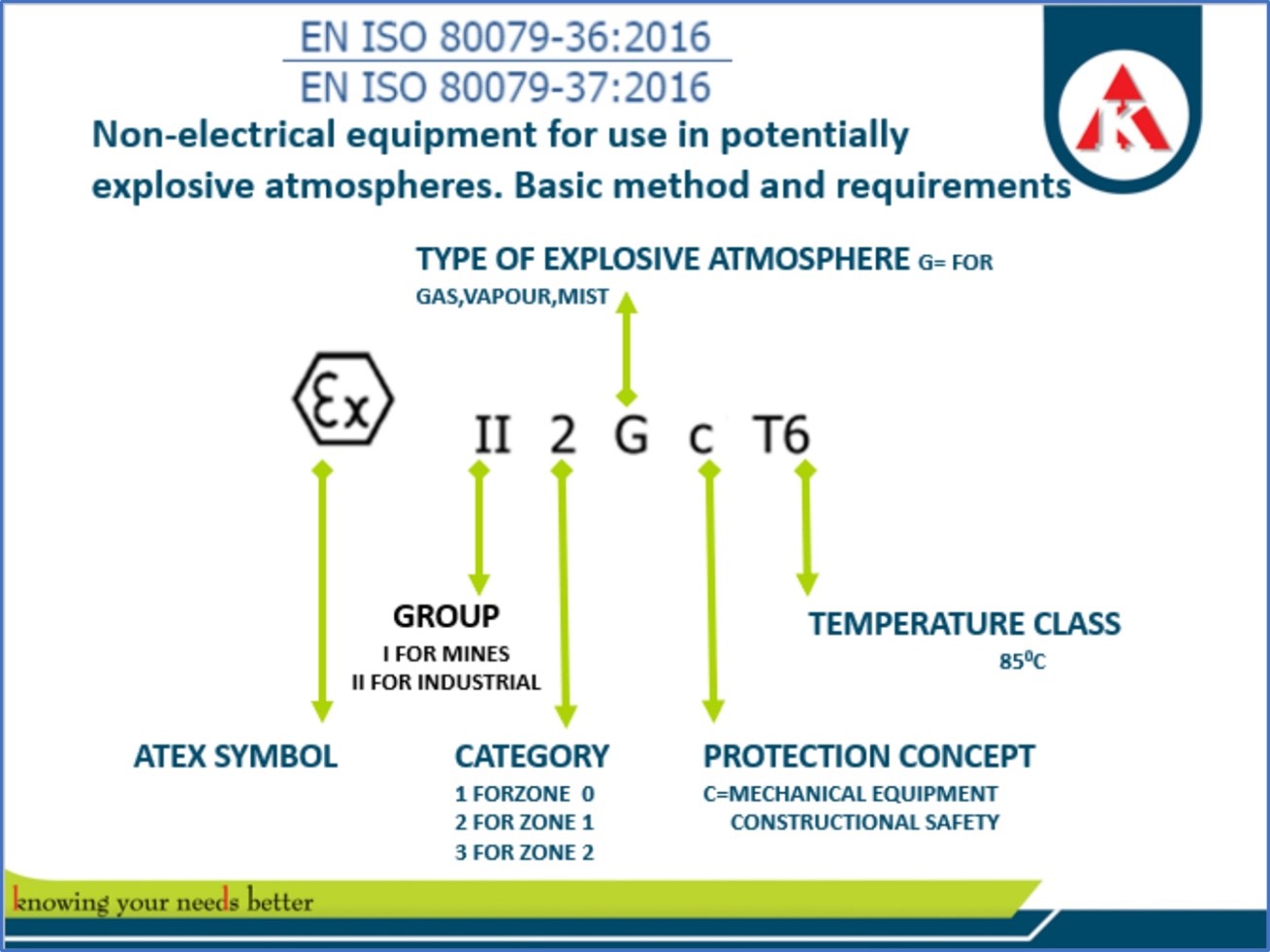

All fall arrest systems need to be used in potentially explosive area needs to be certified to corresponding Fall Arrest standard (example EN 361 for harness) as well as to ATEX standard in compliance with -

EN ISO 80079-36:2016 Explosive atmospheres – Part 36: Non-electrical equipment for explosive atmospheres – Basic method and requirements.

EN ISO 80079-37:2016 Explosive atmospheres – Part 37: Non-electrical equipment for explosive atmospheres – Non-electrical type of protection constructional safety “c”, control of ignition sources “b”, liquid immersion “k”.

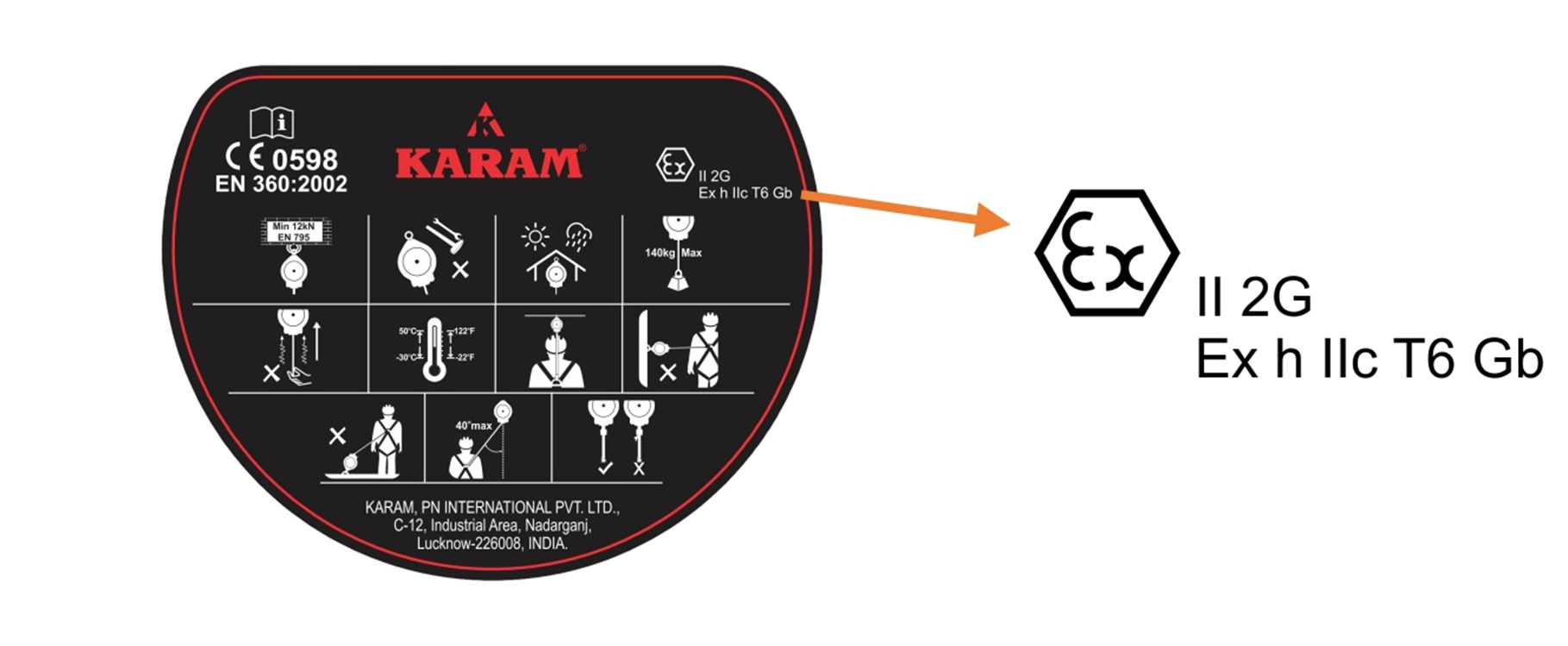

Here is what ATEX marking looks like on a typical KARAM product label -

Conclusion:

Only a few manufacturers in the world have a comprehensive ATEX certification as KARAM. For Hydro Carbon Industry ATEX certification is our biggest strength.

Only a few manufacturers in the world have a comprehensive ATEX certification as KARAM. For Hydro Carbon Industry ATEX certification is our biggest strength.